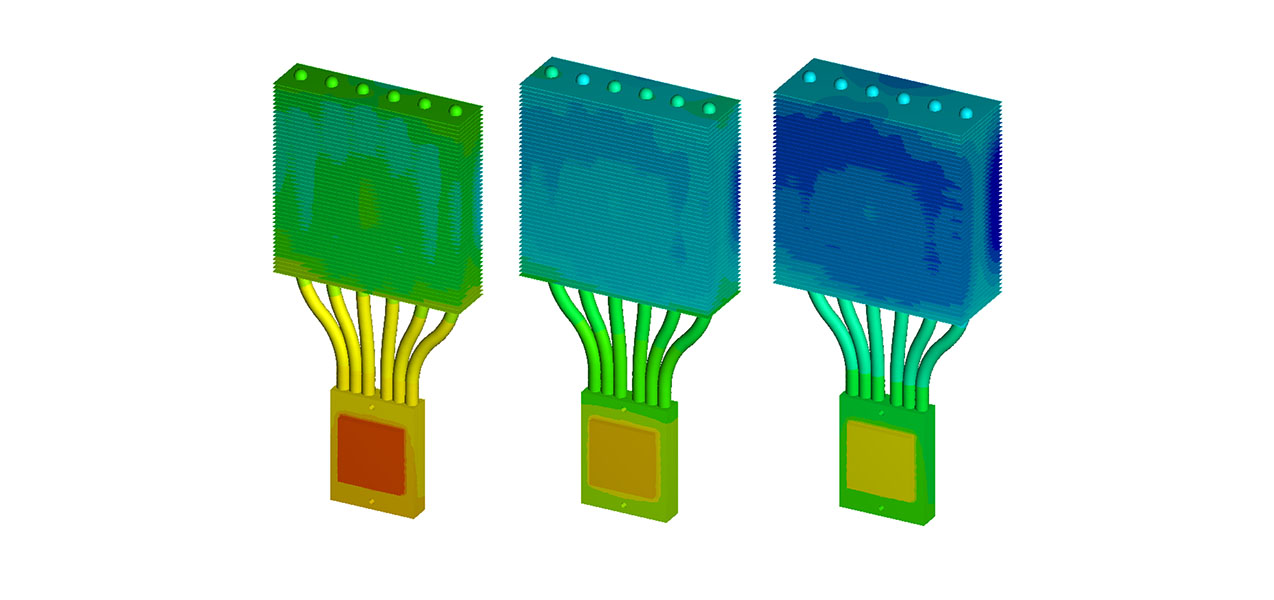

If desired, our products can be developed, tested and optimized with the help of CFD simulation (abbreviation for Computational Fluid Dynamics). The advantage is the detailed visualization of complicated processes in liquid or gaseous media and their interaction with other fluids, gases or particles. Navier-Stokes equations and a large number of models based on them play a central role in the entire calculation. The simulation of complex flows makes it possible to map and calculate a multitude of parameters in a virtual environment. The knowledge gained from this flows directly into the product development and shortens the development time. Furthermore, these results provide a detailed insight into the function of the components. Problems and damage can be identified in advance and avoided cost-effectively – testing on prototypes is largely unnecessary. Our experience and the mathematical characterization of our components and groups, such as heat pipes or Peltier modules, which runs parallel to the CFD, also enable an exact validation of the individual components, allowing us to integrate our experience directly into your project.