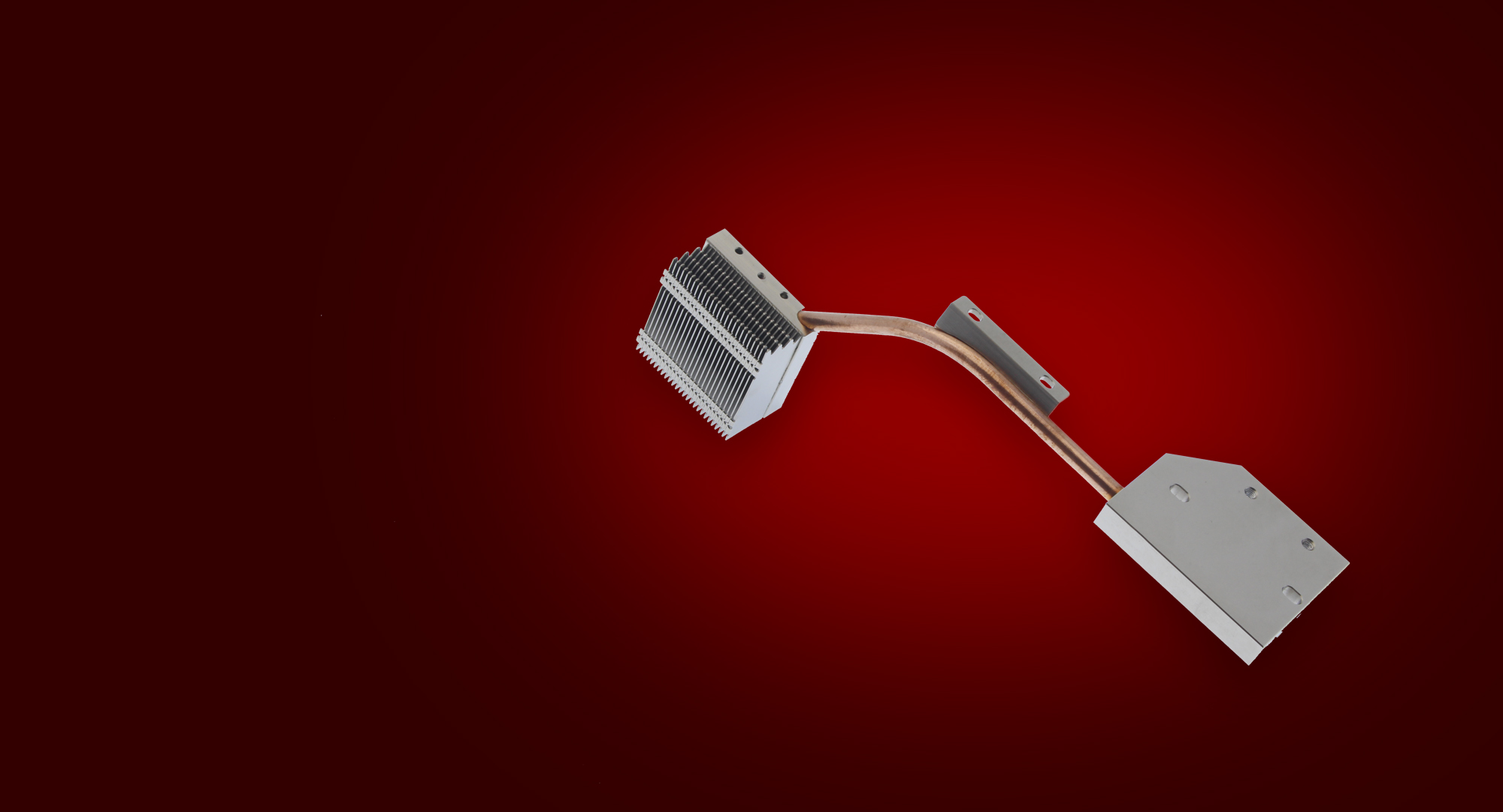

Effectiveness and Efficiency – Heat pipes achieve amazing results in thermal management and are an essential part of it. If heat pipes are combined to a heat sink by appropriate procedures, not only the use in numerous application areas is ensured, but the cooling capacity is optimized many times over. The heat is efficiently dissipated from hot spots and is also predestined for use in limited installation environments. The combination of heat pipes and heat sinks allows a long distance. These components can be expanded with a variety of manufacturing components.

Heat sinks are heat exchangers which exist in various sizes and shapes. They transfer energy in the form of heat to another medium, such as air. This has only a small heat capacity and therefore absorbs only a small amount of energy. For maximum benefit, a surface as large as possible is therefore required in order to be able to release more energy. This effect is increased by so-called fins or ribs. Heat sinks are usually made of copper, aluminium or, in rare cases, silver. Aluminium heat sinks have the advantage that they have a comparatively low weight even with larger components. However, they do not always provide optimum heat conduction. Copper, on the other hand, is heavier, but also much more resistant. A further advantage results from the fact that the metal conducts heat much more effectively. However, the high weight can be problematic in some applications. In combination with heat pipes, aluminium can be used as copper interface or fin material to create the optimum heat sink.

We offer cooling systems – tailored to your project. For our standard heat pipes we are happy to advise you. Of course we also realize customized solutions for you.

Simulation

Heat sinks are heat exchangers which exist in various sizes and shapes. They transfer energy in the form of heat to another medium, such as air. The heat capacity of these media are very low and therefore they only absorb small amounts of energy. For maximum benefit, a surface as large as possible is therefore required in order to be able to release more energy. This effect is increased by so-called fins or ribs. Heat sinks are usually made of copper, aluminium or, in rare cases, silver. Aluminium heat sinks have the advantage that they have a comparatively low weight even with larger components. However, they do not always provide optimum heat conduction. Copper, on the other hand, is heavier, but also much more resistant. A further advantage results from the fact that the metal conducts heat much more effectively. However, the high weight can be problematic in some applications. In combination with heat pipes, aluminium can be used as copper interface or fin material to create the optimum heat sink.

Heat pipes

In some cases, cooling by means of a conventional solution is not sufficient for the proper operation of a component. Either the position of the hot spot offers no space for a suitably dimensioned heat sink or the waste heat is to be removed directly from the case. This can be remedied by heat pipes. These enable heat to be transported to the heat sink. The hollow shape and the copper wire mesh inside, as well as liquids – such as water or ammonia – favour a capillary effect. Due to the design, a continuous cycle is created here.

Depending on your requirements, our range offers heat pipes with sintered or mesh structure (on request also groove structure) – optionally nickel-plated or antioxidant-coated. On customer request we form the heat pipe exactly after drawing and optimize these after arrangement.

Mounting material / TIM

Before installing a heat sink, care should be taken to eliminate surface unevenness with the aid of heat conducting material. A thin film or pad is applied to optimize heat transfer between the hot spot or heat pipe and displace trapped air. In addition, heat conducting discs made of ceramic, silicone or polyimide can ensure galvanic separation. This is particularly recommended for sensitive electronics.

Thermal conductive adhesive provides a better hold. This adhesive usually consists of two components and cures under the influence of heat. In addition, it offers excellent mechanical fastening with good heat transfer at the same time.

We offer a wide range of assembly materials and advise you extensively so that the suitable element is used in your project.